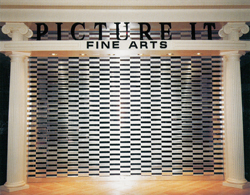

ALUMINUM PANEL ROLL-UP

|

Aluminum Panel Doors combine superior security with attractive design while providing visibility. Aluminum Panel doors can be manufactured to fit openings of any width and height to meet a diversity of commercial and residential applications. Doors can be motor, chain hoist, crank or manually operated. Possible applications include, but are not limited to, storefronts, parking garages, interior counter and shopping-mall security.

|

ARCHITECTURAL SPECIFICATIONS

• GENERAL SPECIFICATIONS

Work Included

Aluminum Roll-Up Doors will be designated as Model AR__as manufactured by Best Roll-Up Door, Inc.

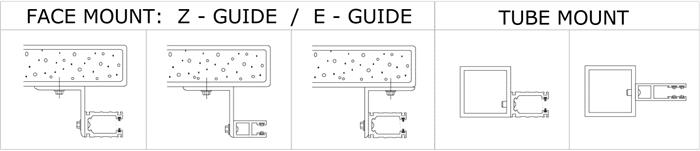

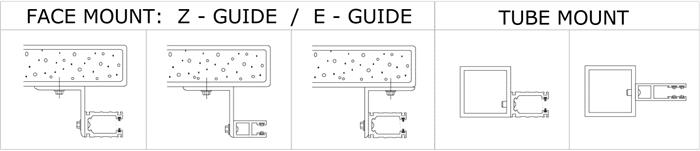

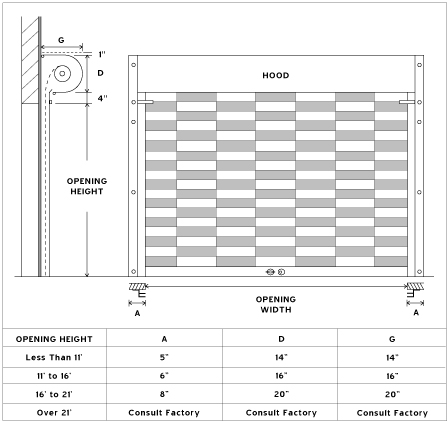

- Mounting: The door can be face mounted or mounted between jambs of a prepared opening.

Related Work

Opening preparations miscellaneous or structural steel, field painting or finish, access panels, electrical wires, wiring, switch connection, conduit will be handled by the appropriate trades.

• PRODUCT SPECIFICATIONS

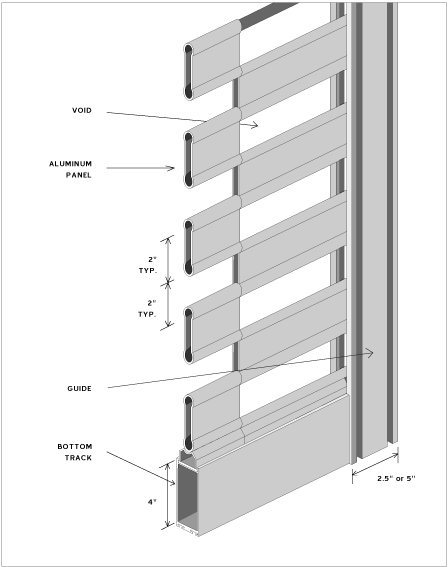

Curtain

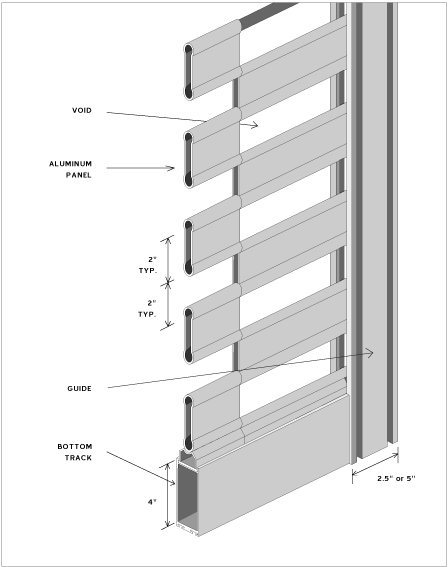

- Slats: Extruded in continuous lengths of anodized 6063-T6 aluminum, interlocked to form curtains. Dual-faced configuration.

- Gauge: Aluminum slat thickness shall be no less than 16 gauge and no more than 8 gauge on each side of dual-faced slats.

- Endlocks: To accomplish slat alignment and serve as a wearing surface endlocks are fitted to each end of alternate slats.

- Anodizing: All aluminum parts are anodized. Mill finish and shiny bright-dip anodized finish is also available.

Bottom Track

Curtain is reinforced with an extruded 6063-T6 aluminum tube that can be further reinforced for wider openings.

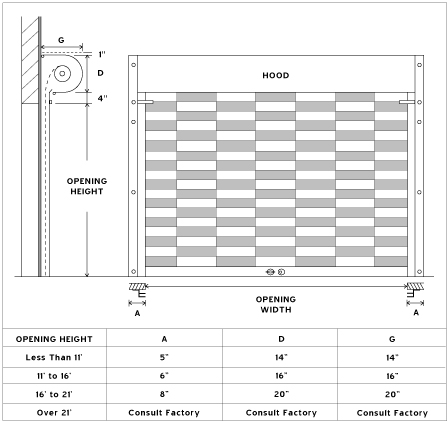

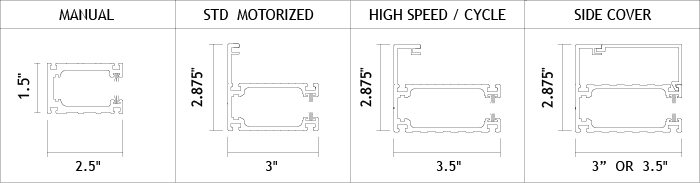

Guide and Wall Angle Assembly

- Guides/Wall Angles: Extruded aluminum channels at both sides shall serve as guides. Wall angles shall be either aluminum or steel with minimum thickness of 1/8". Structural steel tubes can also be used in lieu of wall angles. Guide weatherstripping on inside and outside shall be provided.

- Depth of Guide: To be of appropriate size to allow slat penetration and to restrict horizontal slat movement.

Windload

Aluminum Roll-Up Door construction is designed to withstand windload of up to 60 PSF in a fully closed position, and can be designed to withstand higher windload upon request.

Bracket Plates

- Bracket Plates: To support the curtain and the counterbalance, the bracket plates shall be provided with minimum thickness of 1/4".

- Drive End Bracket Plate: The bracket plate on the drive-end is to be fitted with a sealed ball bearing.

Spring Counterbalance

- Counterbalance: Housed in a steel pipe, maximum deflection of 0.03" per foot of door width is achieved by having the appropriate diameter and wall thickness.

- Springs: Helical torsion with a 25% overload factor for ease of operation and are greased packed mounted on a cold rolled steel inner shaft.

• EXECUTION

OPTIONS

- Endlocks: Continuous endlocks are available.

- Windload: Custom windloads are available.

- Bottom Track: Single steel angle is standard, and double steel angle bottom track is available. Extruded aluminum bottom track is available. Bottom track can be sloped to match contour on finished floor or can be notched to match obstruction on finished floor.

- Sensor Edge: An electronic sensor edge can be added to power operated doors to reverse the door travel upon encountering an obstruction for safety.

- High Cycle Springs: Can be obtained for motorized doors that require 50,000 to 100,000 cycles. Very high cycles in excess of 100,000 are also available.

- Powder Coat Finish: The door can be powder coated in variety of colors.

- Pass Door: Hollow metal pedestrian door within roll-up door can be obtained in a 3' x 7' or 3' x 6' 8" size. Hinged to roll-up door guide the hollow metal door frame will swing clear of opening when desired. Hardware includes heavy duty hinges and handicap-lever lock set.