STEEL ROLL-UP

|

Steel Roll-Up Doors can be manufactured to fit openings of up to 40' in width, and to meet a diversity of commercial application requirements. Doors can be obtained in prime finish or galvanized steel, and can be motor, chain hoist, and crank or manually operated. Possible applications include but are not limited to warehouses, loading docks, aircraft hangers, crane-way openings, and small opening protection. A combination with Aluminum Grille Door is also available for air ventilation, consult factory.

|

ARCHITECTURAL SPECIFICATIONS

• GENERAL SPECIFICATIONS

Work Included

Steel Roll-Up Doors will be designated as Model S__## as manufactured by Best Roll-Up Door, Inc.

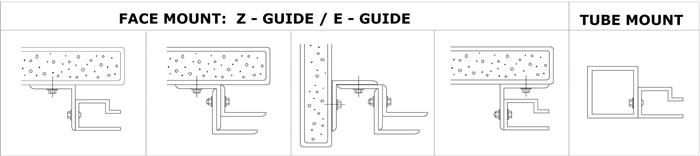

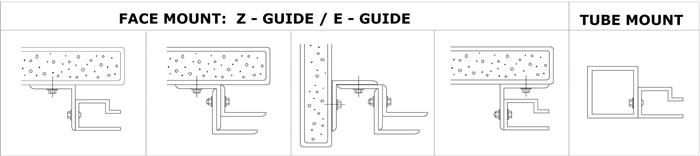

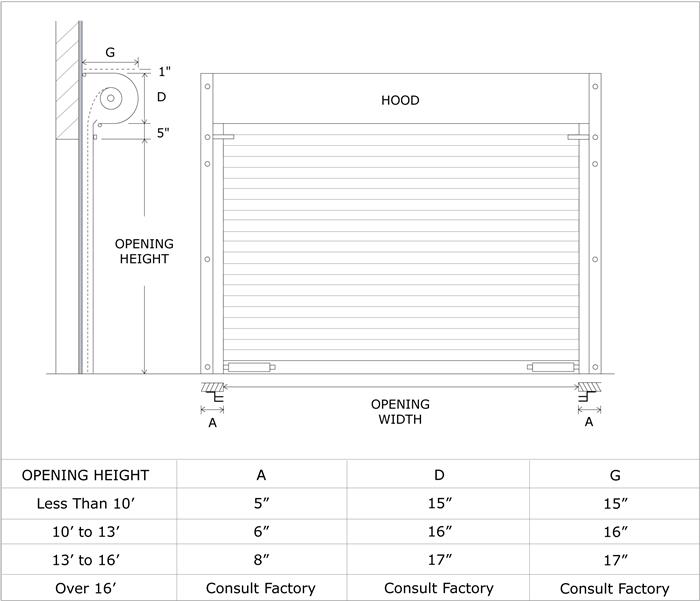

- Mounting: The door can be face mounted or mounted between jambs of a prepared opening.

• PRODUCT SPECIFICATIONS

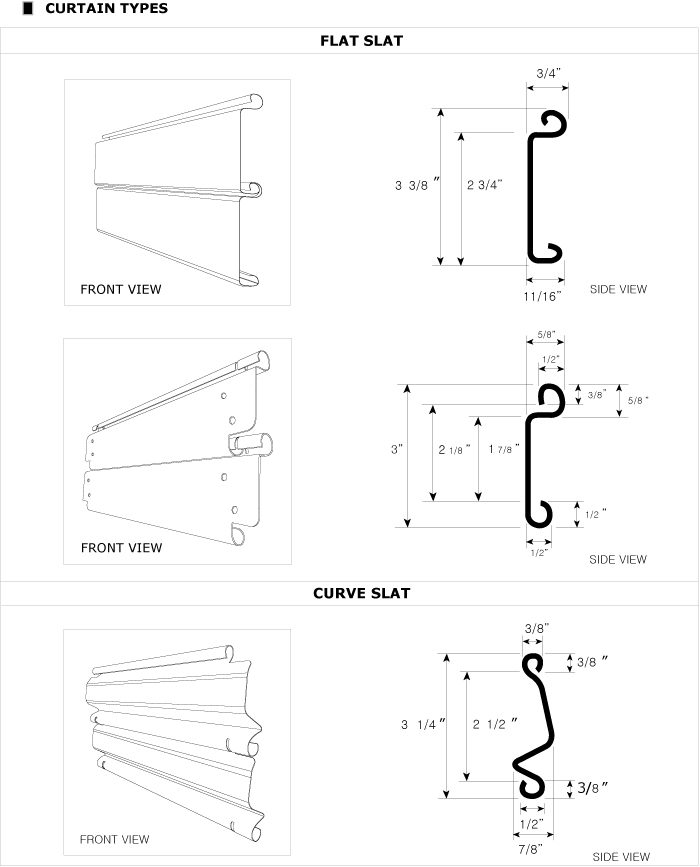

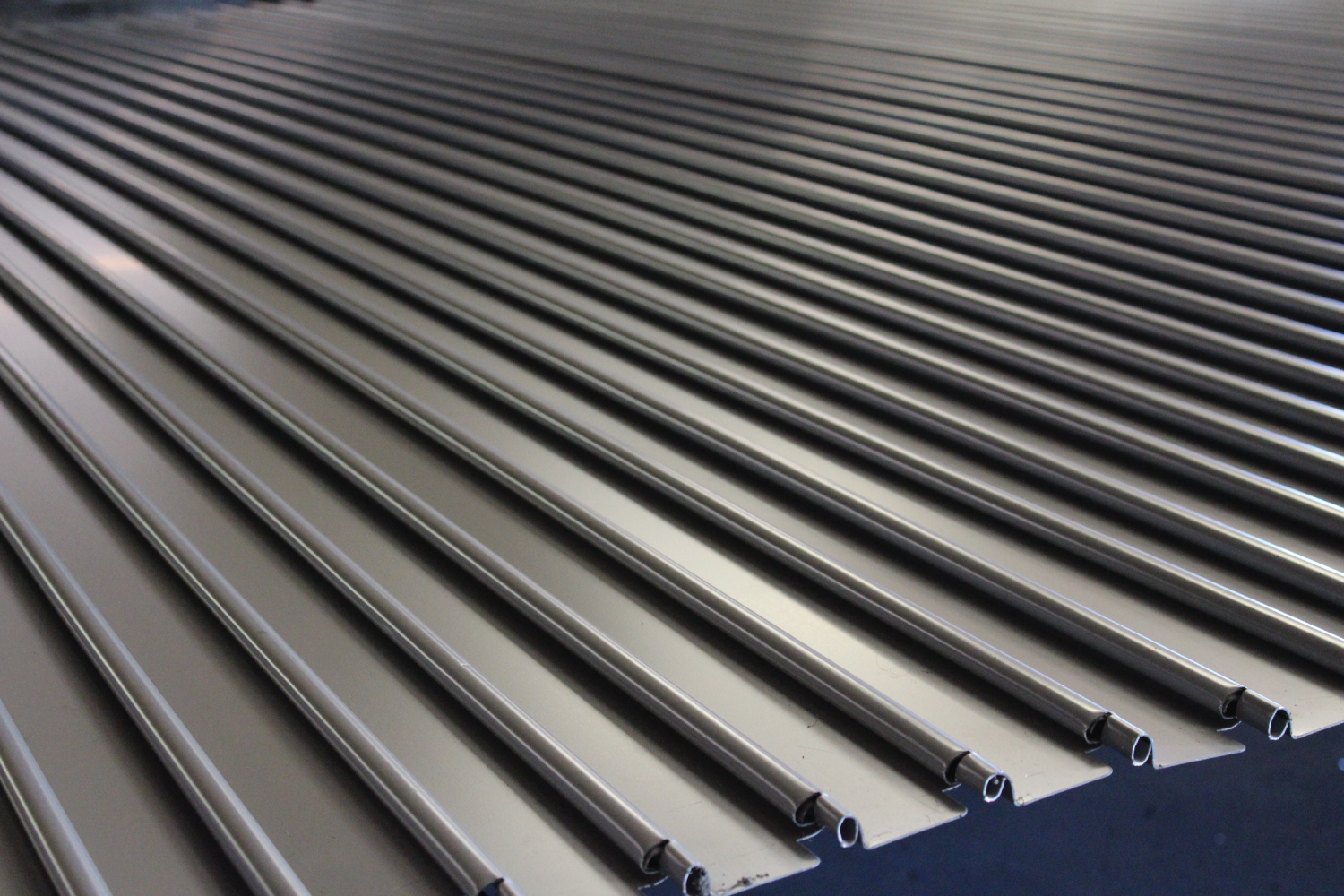

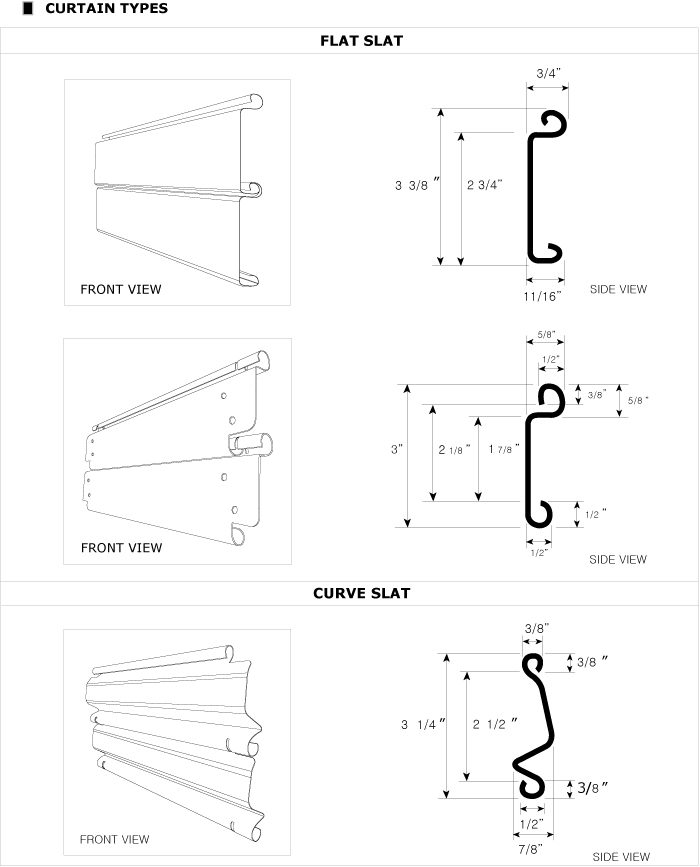

Curtain

- Slats: Formed in a cold-roll process in continuous lengths of galvanized steel interlocked to form curtains.

- Gauge: Available steel slat thicknesses are 18, 20, 22 and 24 gauge..

- Endlocks: Endlocks are fitted to each end of alternate slats to achieve slat alignment and to serve as a wearing surface..

- Galvanizing: Zinc coated.

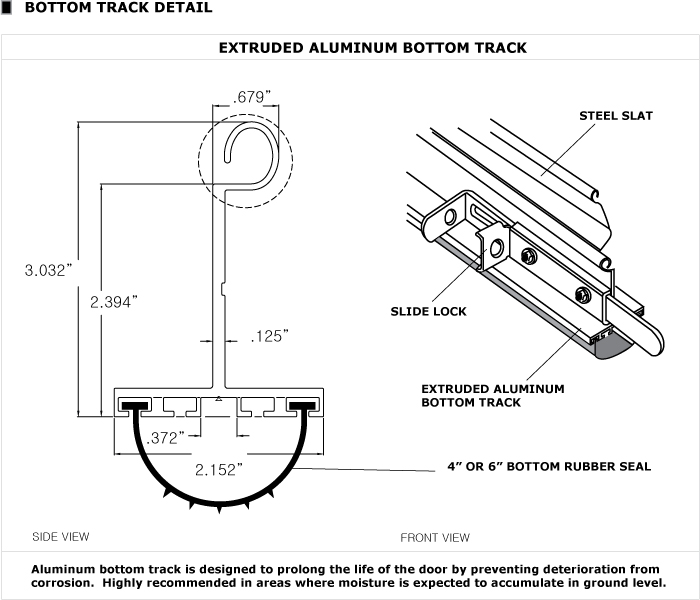

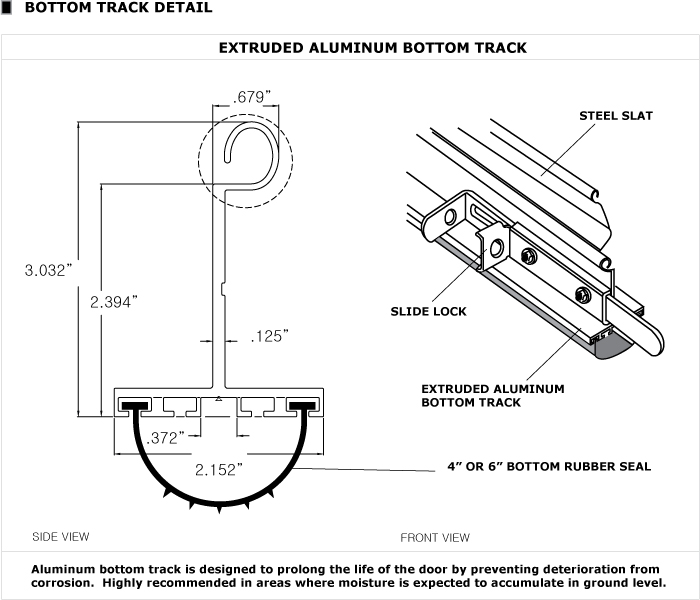

Bottom Track

Reinforcement of curtain is achieved by using a bottom track consisting of either extruded aluminum angle or structural steel angle.

Guide and Wall Angle Assembly

- Guides/Wall Angles: Guides can be constructed using steel angles or a steel channel. Wall angles of structural steel shall have a minimum thickness of 1/8".

- Depth of Guide: To be of appropriate size to allow slat penetration and to restrict horizontal slat movement.

Windload

Steel Roll-Up Door construction is designed to withstand windloads of up to 20 PSF in a fully closed position, and can be designed to withstand higher windloads upon request up to 95 PSF.

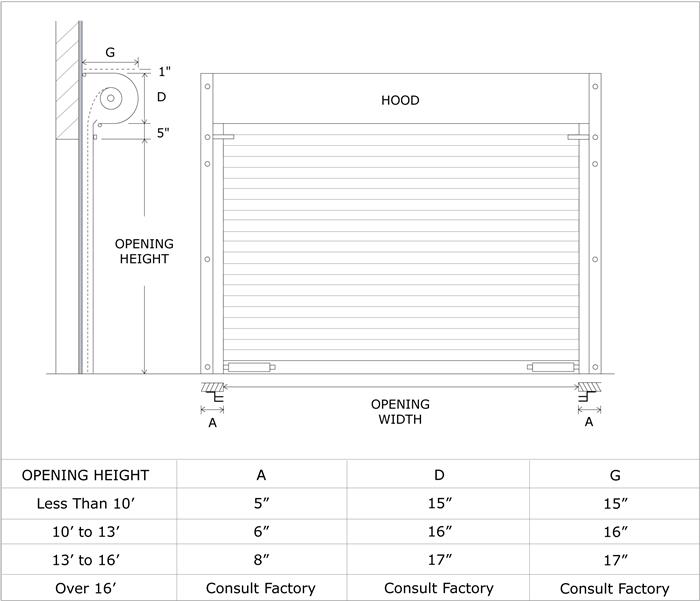

Bracket Plates

- Bracket Plates: To support the curtain and the counterbalance mechanism, the bracket plates shall be provided with minimum thickness of 1/4".

- Drive End Bracket Plate: The bracket plate on the drive end is to be fitted with a sealed ball bearing.

Spring Counterbalance

- Counterbalance: Housed in a steel pipe, maximum deflection of 0.03" per foot of door width is achieved by having the appropriate diameter and wall thickness.

- Springs: Helical torsion with a 25% overload factor for ease of operation and are greased packed mounted on a cold rolled steel inner shaft.

- Spring Tension: Can be adjusted from outside of end bracket plate.

- Ball Bearing: Sealed in order to minimize wear of pipe shaft rotating around inner shaft.

Hoods

- Hoods: To completely enclose curtain and counterbalance, hoods shall be provided form #24 U.S. Gauge galvanized steel.

- Reinforcing: Hoods can be reinforced laterally to prevent sag.

- Intermediate Hood Supports: Provided where door width exceeds 16'.

Operation

Operation can be manual push-up, chain hoist, waist high crank hoist, or electric motor operation.

Locking

- Slide Bolts: On bottom track for manual push-up operated doors.

- Integral Gearing: Power operator can serve as an additional locking for the door.

- Hand Chain Lock: Consists of a locking bracket mounted on a guide angle.

Finish

Any un-galvanized surfaces will be coated with rust inhibiting metallic primer, except bearings.

• EXECUTION

Installation

Installation to be completed by an authorized representative.

Options

- Endlocks: Continuous endlocks are available.

- Windload: Custom windloads are available.

- Bottom Track: Single steel angle is standard, and double steel angle bottom track is available. Extruded aluminum bottom track is available. Bottom track can be sloped to match contour on finished floor or can be notched to match obstruction on finished floor.

- Sensor Edge: An electronic sensor edge can be added to power operated doors to reverse the door travel upon encountering an obstruction for safety.

- High Cycle Springs: Can be obtained for motorized doors that require 50,000 to 100,000 cycles. Very high cycles in excess of 100,000 are also available.

- Powder Coat Finish: The door can be powder coated in variety of colors.

- Pass Door: Hollow metal pedestrian door within rolling door can be obtained in a 3' x 7' or 3' x 6' 8" size. Hinged to rolling door guide the hollow metal door frame will swing clear of opening when desired. Hardware includes heavy duty hinges and handicap-lever lock set.

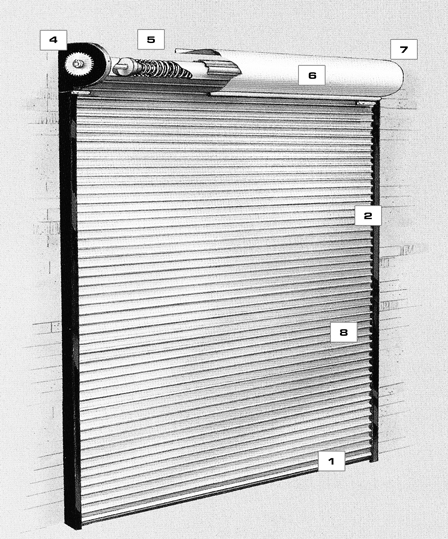

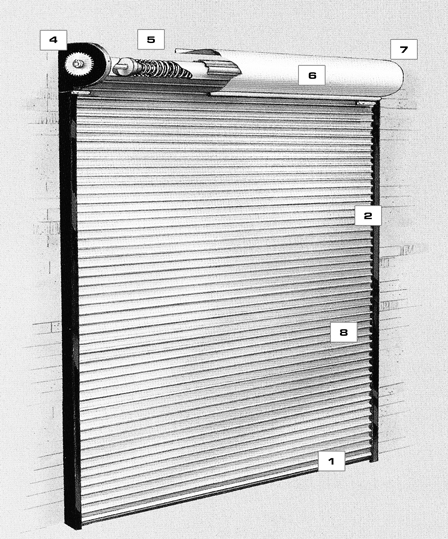

1. Bottom Track

1. Bottom Track

Reinforcement of curtain is achieved by using a bottom track consisting of steel angles. Single steel angle is standard, and double steel angle bottom track is available. Extruded aluminum bottom track is available. Bottom track can be sloped to match contour to finished floor or can be notched to match obstruction on finished floor.

2. Guides

Roll-formed steel guides are fabricated from precisely formed angles and channels with integral windlock bars. They guide curtain travel, and can withstand windloads to 20 PSF. Top of guides are flared to auure smooth transition of the curtain into the guides.

3. Guide Stop

Guide stop installs easily, without fasteners protruding into the guide openings to interfere with door operation.

4. Brackets

Steel brackets support and enclose the curtain coil and spring barrel at either end. Prepunched for easy installation of hood.

5. Counterbalance

Counterbalance assembly consists of a spring barrel, which serves as load-carrying beam, encases counterbalance mechanism, and provides axis around which curtain coils. (Deflection is limited to 0.03" per lineal foot of span.) If needed, barrel rings are involute shapes of malleable iron, or stamped steel, to assure proper counterbalance for all points of travel. Oil-tempered, torsion-type counterbalance springs are wound from heat-treated steel, provide accuracy in balancing door. Barrel plugs connect ends of springs to barrel and tension rod. Tension rod of steel shafting holds fixed ends of springs and carries tensional load of spring counterbalance.

6. Hood Cover

Sheet metal hood covers curtain coil and counterbalance mechanism.

7. Spring Tension

Tension adjusting wheel is mounted outside bracket, on end of tension rod. It simultaneously applies and holds tension of counterbalance, makes adjustment simple.

8. Curtain

Zinc coated Galvanized slats, formed in a cold-roll process in continuous lengths of galvanized steel interlocked to form curtains. Available steel slat thicknesses are 18, 20, 22 and 24 gauge.